Aalborg White® has always been identified with white cement throughout the world. A high quality cement that you can find everywhere from Park Avenue skyscrapers in Manhattan to the London Olympics structures to the Lindholm High Museum in Nørresundby, Denmark.

Cement is a finely ground mineral powder which reaches solid state through a hydration process when mixed with water, taking a stone-like consistency and maintaining this property over time. Clinker, a fundamental component of cement, is a semi-finished product resulting from burning limestone and other natural minerals at high temperatures.

The distinctive feature of white cement is its color. Such whiteness is obtained thanks to very pure and scarce raw materials, the use of complex production processes and an extremely rigorous quality control which allow this material to be used in complex architectural designs and sophisticated aesthetic applications.

White cement is used as a hydraulic binder together with natural and artificial aggregates, such as sand and gravel, to produce mortars, plasters, concrete and premixed materials.

The peculiarity of AALBORG WHITE® limestone is the lack of contamination from sand and clay, a circumstance that makes it very pure, ideal for the production of white cement. The combination of this pure raw material, high-quality sands and kaolin, advanced technology, a specialized workforce and over 100 years of experience have made AALBORG WHITE® cement unique in the world for its properties such as high reflection, high resistance, low alkali content and high resistance to sulphates. As the world leader in the white cement market with the Aalborg White® brand, Cementir offers a wide product range which complies with the best international standards. Our industrial processes are inspired by Group consolidated best practices that guarantee our customers a unique quality and reliability over time. Our research quality technical centre (RQT) has a worldwide reputation for international patents, awards and multiple collaborations with prestigious universities.

D-Carb® is a CO2-reduced white cement that maintains the high performance standards similar to Aalborg White® CEM I 52.5R while reducing the carbon footprint by 15%.

- Energy saving: light reflection reduces solar absorption and the consequent accumulation of heat, allowing savings in lighting and air conditioning of the rooms.

- Reduction of heat accumulation: covering buildings with reflective materials reduces solar absorption and the consequent heat accumulation.

- Optimization of construction and maintenance costs: white cement allows to obtain coloured cement products, reducing construction costs and subsequent maintenance costs.

- Greater road safety: white concrete road barriers increase visibility and improve safety because they keep a bright colour over time in wet and poor lighting conditions.

- Ready-mixed concrete

- Prefabricated products: concrete elements produced with an industrial process

- Artificial stones: decorative elements for embellishment and finishes

- Pre-mixed products: made with cement, aggregates and other components

- UHPC: ultra-high-performance concrete for thin structural and aesthetic concrete elements with high mechanical, chromatic and resistance

- GRC: glass fibre reinforced concrete - for very thin, bent and light panels for new buildings and renovations

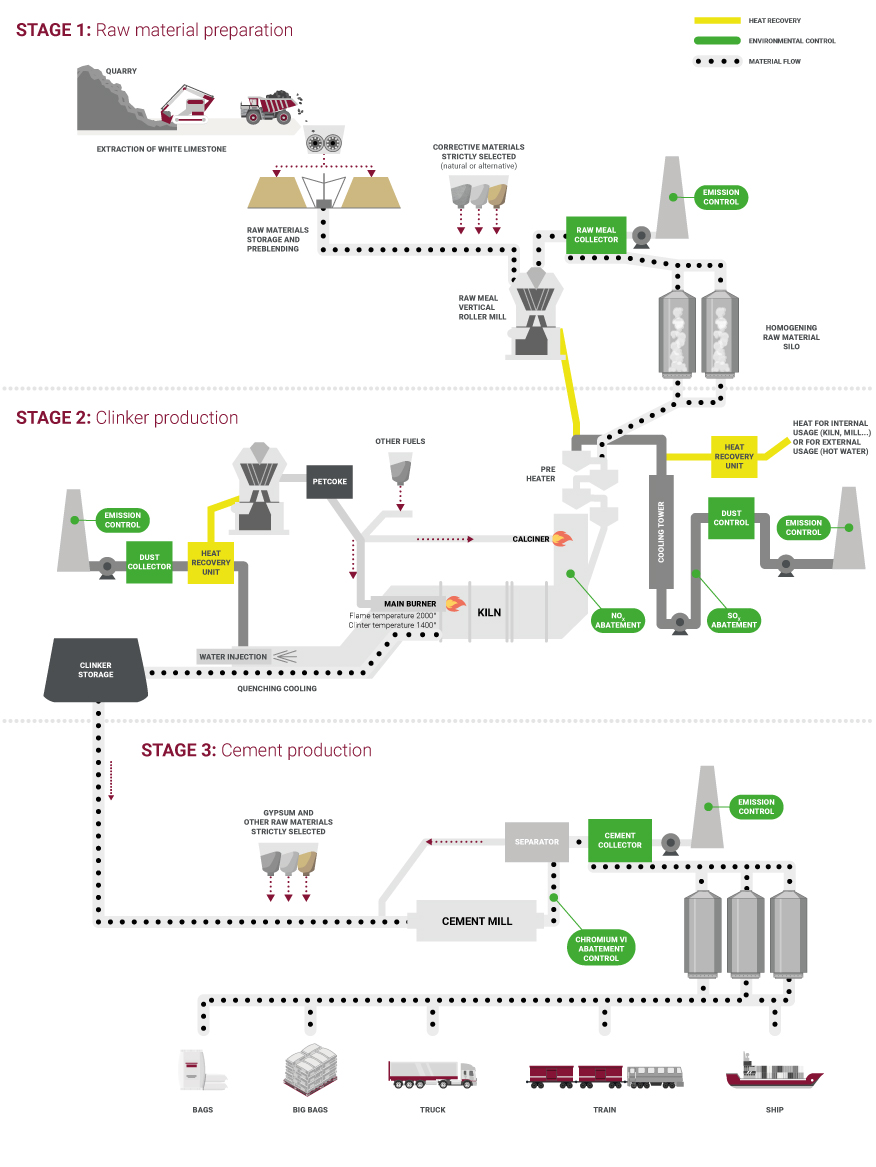

White cement production process

STAGE 1 – RAW MATERIALS PRODUCTION & PREPARATION

Mining or sourcing strictly selected raw materials (to guarantee desired clinker/cement whiteness) to produce a suitable dry powder called raw meal composed of defined proportions of Calcium (C), Silica (S), Alumina (A) to feed the kiln.

STAGE 2 – CLINKER PRODUCTION

Heating the raw meal to evaporate water, decarbonate and form the main components of clinker (C3S, C2S, C4AF, C3A)

- Heat is produced by a fuel mix composed of traditional fuels and to a limited extent , permitted alternative fuels. To guarantee whiteness , the fuels must have a very low ash content

- Before being stored , clinker is quenched with a mix a water and air to secure its hydraulic properties and desired whiteness

- Heat recovery is maximized for internal use (e.g. providing hot air to kiln or calciner combustion, drying raw materials or fuels) or external use (e.g. electricity or hot water for local community)

- Gas emissions are controlled on a continuous basis with abatement of relevant components (SO2, NOx, HCl, dust, etc…)

STAGE 3 – CEMENT PRODUCTION

Mixing and grinding clinker with other raw materials depending on cement types at adequate fineness to reach the desired cement characteristics (strengths, expansion, color….)

QUALITY CONTROL

is done on all input materials & fuels , at every step of the process, on clinker and cement

We offer a wide range of products: grey cement, white cement, aggregates, concrete, value-added products, trading.

We have executed projects all over the world, supporting our customers in all stages of implementation by using cutting-edge technologies.

We are a Group with an Italian soul but a truly international mentality. We have registered offices in the Netherlands and operations in 18 countries.